Understanding Different Types of Roofing Valleys

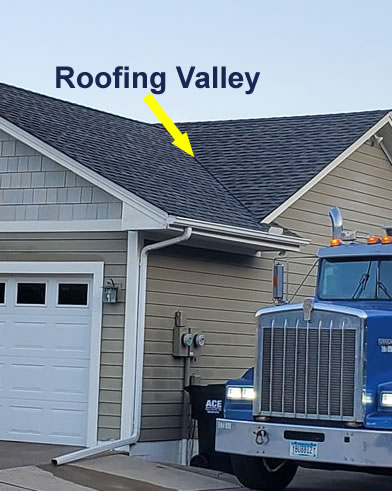

The above photos show a closed (woven) roof valley vs. an open metal roof valley.

Understanding Different Types of Roofing Valleys

What are roof valleys? A roof valley is a channel created where a roof changes direction or angles. Usually, a “V” or “W” shaped metal piece is placed in the valley to channel water off your roof. Roof valleys are very important for a "roofing system" to work correctly and must be done right and taken care of to keep them in good condition. Sadly though, few homeowners get into the design details of their roofs or how they actually work.

There are two basic roof valley types:

Open Valleys

Roofs that feature open valleys use "V" or "W" shaped metal pieces at the center of the valley. The sloping roof planes then stop some inches short of this centerline, leaving the valley open. The V or W shaped metal pieces used as centerlines could be Galvanized, Copper, Aluminum, Zinc Alloy, or Steel coated. Refer to your local area building codes as to which materials to use. The recommended minimum is 28-gauge galvanized/coated steel.

To protect the valley from moisture, the metal flashing is sandwiched between water and ice shield. The sloping roof planes stop at this waterproof lining on both sides, leaving the valley open to channel water off the roof.

Closed Roof Valleys

In closed roof valleys, the roofing shingles are continuous over the valley so that no flashing is visible. Closed roof valleys, though, can still use metal valley flashing depending on the choice of shingles. If you are confused with all these valley style variations. Don't worry because what people choose to call the roof valleys doesn't really matter. Knowing how the valley applications are created is what matters as it helps identify potential areas of failure in the future. It is essential to know the details of the roof valleys to decide which style is best for your particular roofing system.

How the open and closed valley styles are created

The key is to line the valley with waterproof materials (ice and water shield or tar paper) and stop the shingles short of the centerline leaving the waterproof materials exposed. The moisture is kept out using a combination of metal flashing and ice and water shield. Here is how a proper open valley structure is done:

- Line the center of the valley with a row of ice and water shield (width may vary)

- Install metal flashing on top of the ice and water shield.

- Sandwich the metal with the second row of water and ice shield.

- Cut the shingles along the line created by this new row of ice and water shield, leaving the metal open to channel water off the roof.

You can do two types of metal flashing: the “V” (uncrimped flashing) or the "W," i.e., with a crimp down the center. The latter is efficient in preventing cross-wash i.e. when fast-flowing water from one side of the roof flows across the valley and up beneath the shingles on the adjacent roof slope. You can also prevent cross-wash by sealing the shingles where they meet the roof valley.

Not all metal valleys are created equal. Remember to use at least the minimum recommended gauge metal in the valley structure, too thin and it can be damaged by debris. Too heavy and it's going to be expensive and harder to work with.

How the closed valley structures are created

Here, the key is to cover over the valley using the roofing shingles themselves. Closed valley structures feature waterproof materials, too, albeit they are covered by the roofing shingles. Here's how a closed roof valley is created.

- Line the center of the valley with a row of impervious ice and water shield. (width can vary)

- Place roof underlayment lining. While closed valleys don’t need metal flashing, it’s good practice to place a couple of layers of roll roofing before laying the shingles.

- Install shingles through the valley.

Because of installation expenses and our attraction towards aesthetic structures, we have two common types of closed roof valley:

Woven Valleys - The shingles are installed in a traditional sense, i.e., where the two sloping planes meet, the shingles are then interlaced or woven such that the seam matches the contours on the roof. The shingles are just snuggled into the valley avoiding the use of nails within 6-inches of the valley center.

Woven valleys are better created from traditional strip shingles lest they “bridge” the valley leading to leakages as is the case with architectural shingles. Additionally, if not laid carefully, the shingles on a woven valley can create unsightly bumps and lumps leading to a weird-looking roof.

Cut Valley - This is a closed roofing valley style that is used to give the roof a cleaner, sharper appearance. It's very practical where one roof slope is steeper than the other. So, you begin by installing shingles on the lower adjacent roof slope and let the roof-covering extend through the valley line. Next, install shingles on the higher slope but cut them parallel just short of the valley's centerline. This way, water flows from the steeper slope and onto the lower slope shingles.

A variation of the cut valley is the "California Cut Valley" where instead of bringing the high layer across the valley and cutting it parallel at the centerline, you run a row of shingles vertically down the valley, ensuring the nailing edge is along the centerline. Next, overlay the second layer of shingles and offset a few inches such that only the tips reach the valley. This way, there is no need for cutting the shingles apart from typical strip cuts.

So which roof valley type should you go for?

The first sane thing to do is to check with the roofing manufacturer for the particular type of shingle you plan on installing. The general opinion, however, is that open metal valley applications are the best and least problematic over long periods of time.

Here is why:

Reduced friction - Metal flashing offers less friction to rainwater and debris than shingles do. You want debris to slide off your roof easily, not accumulate, and trap water. Also, you want the water to flow off the roof faster than it can penetrate. Metal is the best material to line a roof valley with. Shingles wear down due to snow, ice, wind, and rainwater. Open metal valleys age well with the rest of the roof and will stand the test of time.

Various choices of flashing material – You can go for the dramatic look using contrasting colors or paint the flashing to match the shingles!

The advantages of open roof valleys are that the basic structure is easy to install. No special skills are needed, unlike in the closed case where care and attention to detail are required when lining or weaving the shingles over the valley. Installation is quick, and the metal flashing protects the valley for a long time. Not all open roof valleys look weird, especially if you get copper or painted flashing that accentuates the shape and style of your roof.

The disadvantages of open metal valleys, though, are that the cost of installation is a bit higher because of the price of the materials and the labor required to install them. Open metal valleys also lack the aesthetic appeal of closed valleys. For example, on a roof where the two sloping roof planes have different pitches, the closed cut valleys can make the entire roof appear as if it's draping over the surface. An open valley, on the other hand, doesn't look as good on valleys where the planes have different slopes.

Pros and Cons of closed roof valley systems

Closed cut valleys are aesthetically pleasing. Rather than leave a weird-looking exposed piece of metal at the centerline of the valley, shingles are lined and stripped beautifully to leave your roof looking exceptional and almost seamless.

If you want to save money, then go for a closed cut valley. You don’t have to pony up for pre-finished or customized galvanized metals. Just the shingles and the ice-water barrier are all that you need. And the closed valley application can be installed quickly, thereby saving on labor costs.

The caveat of closed roofing valley structures though is that shingles cannot take the same abuse from ice, snow, and the rain beating down as well as the metal flashing does. Therefore, unlike open valleys that age well with the rest of the roof, closed valleys lose their aesthetic appeal faster, aging faster than the rest of the roof because of the amount of water they are required to handle.

Remember: Your roof slopes to the valleys, meaning all of the water accumulates in the valley like a small river. This large volume of fast moving water can wear shingles down much faster than the "field shingles" that make up the majority of your roof. Therefore, expect higher failure rates from those eye-catching closed valley applications. And despite quicker installation time, more skill and attention to detail is needed e.g., when cutting.

The take-home is that not all roofing valleys and roofing structures are created equal; depending on your budget, the look you want and the local building codes you can go for open metal valley, closed cut valley, woven closed valley or California cut valley.

Thunderstruck Restorations Is Your Local Roofing Contractor

Thunderstruck Restorations provides roof replacement and roof repair services throughout Anoka County, Chisago County, Hennepin County, Washington County, Dakota County, Ramsey County, and Wright County. We specialize in the installation of roofing systems from CertainTeed, Owens Corning, Atlas, and GAF.